top of page

FOAM ZZ 330

Fire protection foam:

Combo passes

Flammable pipes in insulation

Non-flammable pipes in insulation

Cables and cable trays

Find out more> Buy on the purchasing platform>

>> PRODUCTS >> FIREPROOF COLLARS >> MOUNTING SET CC S

CC S MOUNTING SET

FIREPROOF COLLAR

Steel segment cover

2 meters

Intumescent insert

3,7 meters

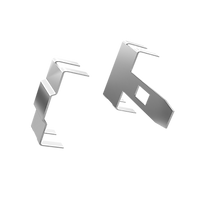

Fastening elements

27 pcs

Connecting elements

10 pcs

The CarboCollar CC assembly kit with the S SLIM segment housing is intended for self-assembly of the CarboCollar CC SLIM at the place of its assembly (e.g. on a construction site). The set includes: A) a steel segmented casing, B) an intumescent insert in the form of a tape, C) a set of fastening elements, D) a set of elements connecting the collar, clip and slotter, labels and certificates. Installation method: 1. Select from Table 1 or 2 the size of the CC flange that you will mount on the pipe. Determine and count the number of segments, after counting, cut or break off some of the counted segments from the casing. Count the number of fasteners and mount them to the housing, mount the connecting elements at the ends of the housing. Then measure and cut off the intumescent cartridge and insert it into the housing. Install the flange with steel pins to the partition. After assembly, mark the finished flange with a label and stick the manufacturer's certificate on the partition. Use an open U-flange to seal elbows.

A detailed assembly diagram can be found in the cardboard box, in the instruction attached to the set. The fire protection collars are delivered without expansion fasteners. The ready-assembled fireproof collar is placed around the pipe, closed and then fixed to the partition with fasteners, the number of which is given in the instructions. When constructing and installing firestop collars, the provisions contained in the CC-IM3 installation manual attached to the firestop collar must be strictly observed.

NOTE: Steel fittings are a separate product and are supplied in a custom kit.

Examples of technical installation of the product:

From the table below (column 3), read the correct length of the segment cover for the given collar diameter and break it off

Place the fastening elements on the appropriate sections of the steel cover from below and bend the ends with pliers. Segment numbers are given in the Table "Mounting data for O-shaped fireproof collars" (Column 7)

Put on one end of the cover the connecting element securing the buckle and the connecting element with the mounting slot on the last segment of the cover. Install these components on top of the cover, opposite to the fastening elements, and bend the ends

Read the appropriate

length of the intumescent

insert for a given diameter

from the table below

(column 4) and cut it off

with a knife

Place the intumescent insert in the previously prepared steel cover of the collar with connecting elements and give the whole collar a round shape.Stick the label and write the size of the collar

Examples of technical installation of the product:

Read the appropriate length of the segment cover for the given diameter of the fireproof collar from the table below (column 3)

and break it off.

Place the fastening elements on the appropriate sections of the steel cover from below and bend the ends with pliers. Segment numbers are given in Table 35 "Mounting data for U-shaped collars" (Column 7)

Read the table below "mounting data for u-shaped fireproof collars "(column 4) the appropriate length of the intumescent insert for a given diameter and cut it off with a knife

Place the intumescent insert in the previously prepared steel cover of the cover with mounting elements installed and give it a U shape

Fireproof collars prepared this way are ideal for installation on pipe elbows

bottom of page